联系我们

与泰克代表实时聊天。 工作时间:上午 9:00 - 下午 5:00(太平洋标准时间)。

致电我们

工作时间:上午9:00-下午5:00(太平洋标准时间)

下载

下载手册、产品技术资料、软件等:

反馈

利用泰克校准服务提高精度和可靠性

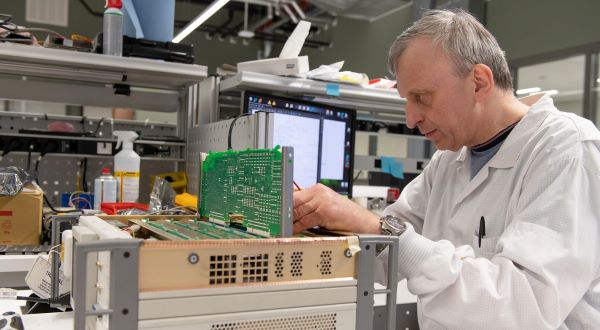

作为一名敬业的实验室管理人员或维护协调人员,您深知在工程和生产运营中保持无可挑剔的精确性和可靠性至关重要。在泰克,我们与您一样致力于追求卓越,我们的校准服务经过专门设计,旨在为您提供实现出色精度和效率所需的工具。

为什么选择泰克?

了解我们的团队合作模式、敬业精神和庞大资源网络如何使泰克与众不同。

Discover the Unbeatable Offering of Tektronix Calibration Services

With Tektronix Calibration Services, you gain much more than just calibrations. You obtain a competitive edge, an unwavering commitment to accuracy, and the confidence to deliver results that surpass expectations.

多品牌 OEM 兼容校准

我们了解您的设备阵容可能由各种品牌组成。无论是何种品牌,我们都能保证始终如一的准确性并遵守制造商规范,确保您的仪器以最佳状态运行,一站式满足您的校准需求。

- 符合 OEM 规范:有了泰克,您可以相信您的仪器是按照仪器 OEM 公布或建议的精确校准点和程序进行校准的。

- 涵盖广泛的仪器品牌:从行业领导者到专营制造商,我们拥有校准各种 OEM 的广泛仪器的知识和经验,这使我们成为您多样化设备阵容的首选校准合作伙伴。

- 全套校准服务交付方案:我们将与您合作,定制最适合您的服务交付方案。目前提供:

- 实验室内服务

- 定期现场服务

- 永久现场服务

- 虚拟现场服务

- 移动实验室服务

现场服务托管校准

作为一名重要的现场服务经理,我们了解您在高效管理分散在各地的现场服务团队时所面临的挑战。确保最短的停机时间、尽可能地提高生产率并优化成本,是实现最佳现场服务运营的基本要素。

泰克现场服务托管校准解决方案使您能够:

- 最大限度地减少停机时间:您可以告别因设备校准和维修而导致的延误。我们负责现场服务工具的校准、维修、更换和处置以及用品、附件和耗材等所有方面的工作,可在您的团队需要时立即提供符合要求的现场服务工具。

- 提高生产率:将现场服务工具的管理委托给我们的专家,您就可以专注于您最擅长的领域 — 提供卓越的现场服务。您可以依靠我们来处理所有校准和维护任务,让您的团队继续专注于高效地为客户提供服务。

High-Quality and Accurate & Accredited Calibration Service

We take great pride in our team of highly skilled Calibration Technicians and Customer Service Engineers who possess an unmatched expertise in servicing a wide range of test and measurement equipment.

You can be confident that every instrument undergoes meticulous calibration procedures, that follows a rigorous certification and accreditation evaluation by independent accredited bodies and follows NIST policies on traceability, ensuring precision, accuracy, and reliability time after time.

With Tektronix, you can rest assured that your valuable assets will be in the hands of professionals who prioritize precision, accuracy, and reliability.

Tailored Solutions for Your Specific Needs

No two engineering and production operations are the same, and we understand that. That's why our approach is not one-size-fits-all. Our dedicated team of Calibration Technicians, Material Handers, and Customer Service Engineers partners closely with you to understand your unique requirements, challenges, and goals. We then develop customized service solutions that align perfectly with your needs, allowing you to focus on innovation and production efficiency.

Trusted Partnership Approach

At Tektronix, we don't just see ourselves as service providers; we see ourselves as your partners in success. Our commitment to building long-term relationships means that you can rely on us not only for superior service but also for ongoing support and collaboration. Together, we can overcome challenges and achieve your operational objectives.

我们的服务遍及各地

泰克拥有完善的,用于测试和测量设备的校准服务实验室网络。遍布全球约 100 家实验室的 1,100 多名经验丰富,且经过认证的技术人员随时准备为您的仪器提供服务。对全球化 公司而言,我们可以成为您的本地合作伙伴,帮助您管理多个地点全部系列仪器的校准计划。

服务中心位置

Calibration White Papers and Case Studies

Lean Calibration Process Case Study

Discover how Tektronix's quality calibrations have helped a large aerospace company improve efficiency, reduce costs, and maintain exceptional on-time calibrations for their sophisticated test and measurement equipment, ensuring a smooth production flow and continuous improvement.

Turnaround Time Savings Case Study

Uncover how Tektronix's calibration services helped a large semiconductor company achieve an impressive 82% reduction in calibration turnaround time, boosting productivity and equipment availability.

Testimonials

On-Demand Calibration Webinar

Quality calibration is the key to confidence in your measurements. Our calibration experts, Jack Wojewski and Guy Robinson, will discuss several factors to consider to ensure the quality of the service you are getting. We'll answer the following questions:

- Why is calibration important?

- What is a quality calibration?

- What should you look for in a calibration provider?

- What should you include in a request for calibration?

- How do you read scope of accreditation documents?

Frequently Asked Questions

What is calibration?

Calibration is the comparison of a measurement device (an unknown) against an equal or better standard. Calibration is all about confidence in the measurement results you're getting and assures you that your measurements are accurate within the specification limits that led you to select the instrument in the first place.

A "typical" commercial calibration references a manufacturer's calibration procedure and is performed with a reference standard at least four times more accurate than the instrument under test. The risks of not calibrating include false passes or false failures in production resulting in costly reworks or discarding products. Traceable calibrations also ensure adherence to the international standards that our commerce relies on.

Even though today's digital instruments are inherently are more stable than their analog predecessors, their tolerances are much narrower than in the past. And even the latest digitizing instruments have analog circuitry—preamplifiers, buffers, etc.—whose performance can change over time. A regular schedule of calibrations will keep your instruments in optimal condition to support your design, troubleshooting, and manufacturing work.

Why should I calibrate my instrument?

Calibration ensures measurement accuracy. Routine calibrations are your prescription for the continued health and performance of your instrument. There are also costs and risks associated with not calibrating equipment regularly.

Calibration should be part of your engineering process. It validates your measurements over a period of time and reduces the risk of rework, recalls, returns and repairs. With proper calibration you can be more efficient with your time to market and reduce your total cost of test. In the engineering lab, inaccurate measurements can distort your findings about the behavior of an emerging design. You don't want to go through unnecessary design rework because your instrument was inaccurate during design validation.

There also may be regulatory requirements stipulating a regular calibration schedule. Penalties for non-compliance from an audit may be fines, loss of business, plant shut down or worse.

Some of our equipment is difficult to move. How do we get it calibrated?

Sometimes sending in an instrument to get calibrated isn't an option. From onsite service to local service centers, there are different delivery options available to meet your needs.

Local service centers – Local service centers offer free pick-up and delivery within the locality of the center, and a broad scope of accreditation which helps minimize third-party costs.Tektronix has 27 North American and 18 International locations. Find a service center nearest you.

Periodic onsite service – With this option, customers can plan ahead and avoid having to take equipment out of service to minimize impact on your design and production schedules. This is also the best option to calibrate sensitive or large equipment that can’t be moved.

“Virtual onsite service” – With the concerns surrounding the ongoing COVID-19 pandemic, we’ve also introduced a new “virtual onsite” service where we dedicate the resources and standards that would have been used for onsite service but perform the service in our service center. Virtual onsites, combined with pickup and delivery service, allow for appropriate social distancing where required and offers the same fast turnaround times you would experience with a normal onsite service event.

What is a calibration certificate?

A calibration certificate is an essential and official document that serves as a record for the calibration of instruments, offering a critical aspect of traceability to the National Institute of Standards and Technology (NIST). The integrity and accuracy of this certificate are indicative of the credibility and validity of the organization conducting the calibration. A Calibration Certificate accompanies the instrument when it's returned to its owner, documenting crucial information about the instrument's condition, including out-of-tolerance conditions and special measurement circumstances.

Calibration certificates may vary in format due to geographical and regulatory differences, but they typically include details such as calibration dates, environmental conditions, in-tolerance or out-of-tolerance conditions, traceability statements, and information about the calibration procedure and intervals. Understanding and preserving this certificate is vital for assessing measurement accuracy and mitigating risk associated with uncertainties in measurements.

What is your calibration interval?

Determining the right calibration interval for your test and measurement equipment depends on many factors with no “one size fits all” approach available.

Learn what factors can influence your test equipment’s measurement accuracy and what to consider when determining your calibration interval.

What is metrology?

Metrology ensures that your calibrated instruments deliver accurate results with provable validity. The mission of metrology is to maintain measurement standards, to develop effective new methods, and to ensure that measurements are accepted uniformly around the world.

Why calibrate? Your instruments need to be calibrated against known standards so their results can be trusted to have a universally accepted meaning. Metrology is the science that supports this trust—in both the "meaning" and the measurements:

- Metrology defines calibration and ensures predictable performance from your measurement tools.

- Metrology is the discipline that defines standards and codifies accreditation and traceability.

- Metrology expertise is at the heart of Tektronix' reputation for accuracy, precision, and performance.

At Tektronix, metrology professionals guide calibration policies and procedures at accredited calibration facilities around the world. When you choose Tektronix as your service provider, you get the benefit of an experienced metrology staff plus seasoned technicians applying deep product-specific knowledge.

The result? Services guaranteed to be of the highest quality in the industry.

What is the difference between calibration and validation?

Calibration is the comparison of a measurement device (an unknown) against an equal or better standard, and validation involves documenting that a system or process provides an expected and consistent outcome.

Calibration Terminology

Demystify the calibration process with a better understanding of these key terms.

Helpful Calibration Links

- Asia-Pacific Metrology Program (APMP)

- Bureau International des Poids et Mesures (BIPM)

- Euro-Asian Cooperation of National Metrological Institutes (COOMET)

- European Collaboration on Measurement Standards (EUROMET)

- European Co-operation for Accreditation

- European Cooperation in Legal Metrology (WELMEC)

- Inter-American Metrology System (SIM)

- International Earth Rotation Service

- International Electrotechnical Commission (IEC)

- International Journal of Metrology and Quality Engineering

- International Lab Accreditation Cooperation (ILAC)

- International Organization of Legal Metrology (OIML)

- International Society for Weighing Measure

- International Society for Optics and Photonics (SPIE)

- International Standards Organization

- NCSL International (National Conference of Standards Laboratories)

- Pacific Accreditation Cooperation

- South African Development Community Cooperation in Measurement Traceability