联系我们

与泰克代表实时聊天。 工作时间:上午 9:00 - 下午 5:00(太平洋标准时间)。

致电我们

工作时间:上午9:00-下午5:00(太平洋标准时间)

下载

下载手册、产品技术资料、软件等:

反馈

利用泰克校准服务提高精度和可靠性

作为一名敬业的实验室管理人员或维护协调人员,您深知在工程和生产运营中保持无可挑剔的精确性和可靠性至关重要。在泰克,我们与您一样致力于追求卓越,我们的校准服务经过专门设计,旨在为您提供实现出色精度和效率所需的工具。

为什么选择泰克认证校准?

使用泰克认证校准服务,您获得的不仅仅是校准。我们的专业团队不仅为您提供校准服务,还将成为您团队的坚实后盾,与您携手实现运营目标。您将获得一个值得信赖的合作伙伴,这是为您的成功投资,我们致力于提供持续支持,使您的运营保持最佳状态。我们的 ISO/IEC 17025 认证校准可通过国家和国际计量机构追溯到国际单位制。

探索泰克出色的校准服务

有了泰克校准服务,您获得的不仅仅是校准,您还会获得竞争优势、对准确性的坚定承诺以及对提供超预期结果的信心。

多品牌 OEM 兼容校准

我们了解您的设备阵容可能由各种品牌组成。无论是何种品牌,我们都能保证始终如一的准确性并遵守制造商规范,确保您的仪器以最佳状态运行,一站式满足您的校准需求。

- 符合 OEM 规范:有了泰克,您可以相信您的仪器是按照仪器 OEM 公布或建议的精确校准点和程序进行校准的。

- 涵盖广泛的仪器品牌:从行业领导者到专营制造商,我们拥有校准各种 OEM 的广泛仪器的知识和经验,这使我们成为您多样化设备阵容的首选校准合作伙伴。

- 全套校准服务交付方案:我们将与您合作,定制最适合您的服务交付方案。目前提供:

- 实验室内服务

- 定期现场服务

- 永久现场服务

- 虚拟现场服务

- 移动实验室服务

Mobile Lab Service

A tailored solution designed to meet your unique calibration needs for multiple sites with similar equipment or permanently mounted instruments, all with the convenience of bringing the calibration lab to all your sites, completing equipment calibration within an impressive one workday turnaround time.

Unlock the Potential of Tektronix Multi-Brand Mobile Lab Calibration:

- Ideal for Multi-Site Operations: Our Mobile Lab Service is perfectly suited for multi-site managers and maintenance coordinators, allowing you to streamline calibration across all your locations, eliminating the need for complex logistics and minimizing operation downtime.

- Nationwide Coverage: We are ready to serve customers in all contiguous states of the United States. Additionally, our Transportable Field Calibration Units (TFCUs) can be efficiently shipped to any location, ensuring calibration solutions wherever you operate including, Alaska, Hawaii, Puerto Rico, and the Virgin Islands.

现场服务托管校准

作为一名重要的现场服务经理,我们了解您在高效管理分散在各地的现场服务团队时所面临的挑战。确保最短的停机时间、尽可能地提高生产率并优化成本,是实现最佳现场服务运营的基本要素。

泰克现场服务托管校准解决方案使您能够:

- 最大限度地减少停机时间:您可以告别因设备校准和维修而导致的延误。我们负责现场服务工具的校准、维修、更换和处置以及用品、附件和耗材等所有方面的工作,可在您的团队需要时立即提供符合要求的现场服务工具。

- 提高生产率:将现场服务工具的管理委托给我们的专家,您就可以专注于您最擅长的领域 — 提供卓越的现场服务。您可以依靠我们来处理所有校准和维护任务,让您的团队继续专注于高效地为客户提供服务。

Virtual Onsite

As a lab manager or maintenance coordinator facing space constraints for calibration at your location, we understand the challenges of minimizing critical engineering and production downtime.

Unlock the Potential of Tektronix Multi-Brand Virtual Onsite Calibration:

- Ideal for Space-Constrained Locations: Our Virtual Onsite Service caters to lab managers and maintenance coordinators who face space limitations for calibration at their location. Embrace the convenience of Periodic onsite calibration without the need for dedicated calibration space!

- Seamless Pickup, Calibration, and Delivery: Rest assured, our highly trained Calibration team of Technicians and Material Handlers will work together to seamlessly pick up your equipment for calibration at your site. The calibration process will be expertly completed at our service centers, and your equipment will be promptly delivered back to you within 24 hours.

高质量、高精度和经认证的校准服务

我们拥有一支技术精湛的校准技术人员和客户服务工程师团队,他们在各种测试和测量设备的服务方面拥有无与伦比的专业知识。对此,我们深感自豪。

您可以放心,每台仪器都经过严格的校准程序,由独立认证机构进行严格的认证和认可评估,并遵循 NIST 的可追溯性政策,从而一次又一次确保仪器的精确性、准确性和可靠性。

有了泰克,您就可以放心地将宝贵的资产交到专业人员的手中,他们会优先考虑精确性、准确性和可靠性。

针对您的特定需求量身定制的解决方案

我们深知,没有两个工程和生产运营是完全相同的。这就是为什么我们不提供一刀切方法的原因。我们由校准技术人员、物料搬运人员和客户服务工程师组成的专业团队与您密切合作,充分了解您的独特要求、挑战和目标。然后,我们会根据您的需求量身定制服务解决方案,使您能够专注于创新环节和生产效率。

值得信赖的合作方式

在泰克,我们不仅将自己视为服务提供商,还将自己视为助您成功的合作伙伴。我们致力于建立长期合作关系,这意味着您不仅可以依赖我们提供的优质服务,还可以获得我们持续不断的支持与协作。通过携手合作,我们可以克服挑战,实现您的运营目标。

校准白皮书和案例研究

引荐

按需校准在线研讨会

质量校准是您对测量充满信心的关键。我们的校准专家 Jack Wojewski 和 Guy Robinson 将与您探讨确保服务质量需要考虑的几个因素。我们将回答以下问题:

- 为什么校准很重要?

- 什么是质量校准?

- 校准提供商应当提供什么?

- 校准申请应当包括什么?

- 如何阅读认证范围文档?

常见问题

什么是校准?

校准是按照同等或更优的标准比较(未知)测量设备的过程。校准事关您对测量结果的信心,并确保您的测量数据在规格限制内保持准确,这也是您起初选择仪器的初衷。

“典型”的商业校准是指采用制造商的校准程序,其参考标准在准确度方面比被测仪器至少高四倍。不校准仪器所带来的风险包括在生产中获得错误的“合格”或“失败”结果,这会导致代价高昂的返工或产品废弃。可追溯的校准还可确保遵守我们的商业活动所依赖的国际标准。

尽管当今的数字仪器本身比以前的模拟仪器更加稳定,但其公差比过去窄得多。就连最新的数字仪器也包含模拟电路,比如前置放大器、缓冲器等,但它的性能会随着时间而发生变化。定期校准将使您的仪器保持良好状态,以帮助您开展设计、故障排除和制造工作。

Which industries need accredited calibration services?

While all precision instruments benefit from calibration, accredited calibration (such as ISO/IEC 17025) is often a mandatory requirement in industries with strict quality and safety regulations. This includes aerospace and defense, automotive (especially for IATF 16949 compliance), and medical device manufacturing, where measurement accuracy directly impacts safety and product reliability.

为什么需要校准仪器?

校准能确保测量的精确度。例行校准可保证仪器维持良好的状态和性能。如不定期校准仪器,还可能会产生相关的费用和风险。

校准应该成为您的工程领域不可分割的一部分。它可验证您在一段时间内所进行的测量,减少返工、召回、退货和维修的风险。利用正确的校准,您可以提高产品上市的效率,并减少总测试成本。在工程实验室内,如果测量不准确,可能使新兴设计技术的结果失真。您并不希望设计验证期间仪器不准确而导致不必要的设计返工。

此外,法规可能要求定期进行校准。如果审计不合规,可能会导致罚款、业务损失、工厂停产甚至更糟糕的情况。

有些设备难以移动。如何让它得到校准?

有时将仪器送去校准并不可行。从现场服务到本地服务中心,我们为您提供不同的交付选项,旨在满足您的校准需求。

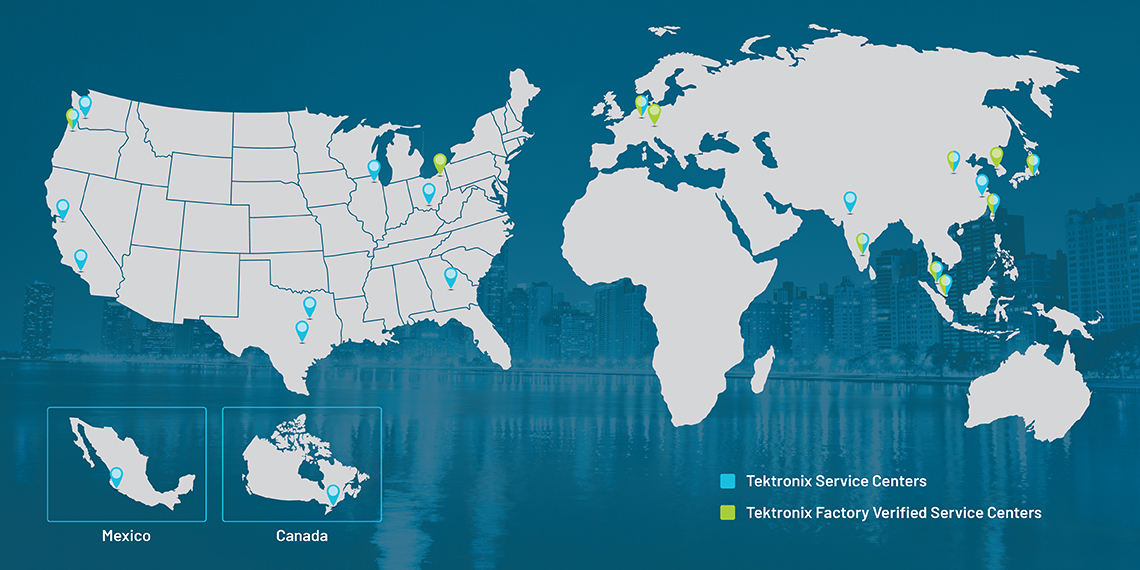

本地服务中心 – 本地服务中心可在所在地范围内提供免费取件和送货服务,并提供广泛的认证服务,这有助于最大限度降低第三方成本。泰克拥有 27 个北美服务中心和 18 个国际服务中心。 查找离您最近的服务中心。

定期现场服务 - 选择此项服务时,客户可提前做出计划并避免被迫停止使用设备,从而最大限度地降低对您的设计和生产计划的影响。这也是校准无法移动的灵敏或大型设备的理想选择。

“虚拟现场服务”- 鉴于对新冠疫情的担忧,我们还推出了一项全新的“虚拟现场”服务,将原本用于现场服务的资源和标准进行虚拟使用,但在我们的服务中心执行服务。虚拟现场与上门取件和送货相结合,得以保持适当的社交距离,并提供与正常现场服务同样的快速周转时间。

什么是校准证书?

校准证书是一份重要的官方文件,可作为仪器校准的记录,是追溯至美国国家标准与技术研究院 (NIST) 的重要依据。该证书的完整性和准确性表明了校准执行机构的可信度和有效性。当仪器归还给所有者时,会随附一份校准证书,记录有关仪器状况的重要信息,包括公差外的条件和特殊测量情况。

由于地域和监管规定的不同,校准证书的格式也可能会有所差异,但通常都包括校准日期、环境条件、公差内或公差外的条件、可追溯性声明以及校准程序和间隔等详细信息。了解和保存此类证书对于评估测量精度、降低与测量不确定性相关的风险至关重要。

什么是计量学?

计量学保证您的校准仪器能以可证实的有效性提供准确结果。计量学的任务是维护测量标准,开发有效的新方法,并确保测量能在全球范围被统一认可。

为何要校准? 您的仪器需要根据已知标准进行校准,使其结果据信具有普遍接受的意义。计量学就是支持这种“意义”以及测量结果信任的科学:

- 计量学对校准做出了定义,并保证您的测量工具具有可预测的性能。

- 计量学是定义计量标准并编纂认证和可追溯性的学科。

- 计量学专长让泰克在准确度、精度和性能方面赢得良好声誉。

泰克计量学专家在全球公认的校准设施内指导您制定校准策略和程序。当您选择泰克作为您的服务提供商,我们富有经验的计量学专家以及老练的技术人员将通过深入的产品知识为您带来校准优势。

服务效果如何?保证为您奉上业内最佳的服务质量。

校准和验证有什么区别?

校准是将测量设备(未知)与同等或更好的标准进行对比,验证则涉及记录方面,即系统或流程是否提供了预期的一致结果。

校准术语

通过更好地理解这些关键术语,可以揭开校准过程的神秘面纱。