联系我们

与泰克代表实时聊天。 工作时间:上午 9:00 - 下午 5:00(太平洋标准时间)。

致电我们

工作时间:上午9:00-下午5:00(太平洋标准时间)

下载

下载手册、产品技术资料、软件等:

反馈

轻松、专业、完善。

泰克可作为您的团队的扩展,交付定制的校准服务解决方案,这不仅能节省时间,还能节省成本,并可确保电子测试和测量设备的准确性。我们与您密切合作,在增强或外包复杂测试与测量设备的校准方面帮助您做出明智的业务决策。每天,成千上万的公司都依赖泰克以具有竞争力的市场价格提供 OEM 质量级别的校准。

- 服务面向泰克、吉时利、福禄克、Keysight、Rohde & Schwartz、Agilent,以及 9000 多个其他的测试与测量设备品牌

- 定制计划选项:现场、本地、发运到工厂

- 快速、可依赖的周转时间

- 完整系列的 Z540 和 ISO 17025 认证校准

- A2LA 认证技术人员

轻松、专业、完善。

泰克可作为您的团队的扩展,交付定制的校准服务解决方案,这不仅能节省时间,还能节省成本,并可确保电子测试和测量设备的准确性。我们与您密切合作,在增强或外包复杂测试与测量设备的校准方面帮助您做出明智的业务决策。每天,成千上万的公司都依赖泰克以具有竞争力的市场价格提供 OEM 质量级别的校准。

- 服务面向泰克、吉时利、福禄克、Keysight、Rohde & Schwartz、Agilent,以及 9000 多个其他的测试与测量设备品牌

- 定制计划选项:现场、本地、发运到工厂

- 快速、可依赖的周转时间

- 完整系列的 Z540 和 ISO 17025 认证校准

- A2LA 认证技术人员

轻松、专业、完善。

泰克可作为您的团队的扩展,交付定制的校准服务解决方案,这不仅能节省时间,还能节省成本,并可确保电子测试和测量设备的准确性。我们与您密切合作,在增强或外包复杂测试与测量设备的校准方面帮助您做出明智的业务决策。每天,成千上万的公司都依赖泰克以具有竞争力的市场价格提供 OEM 质量级别的校准。

- 服务面向泰克、吉时利、福禄克、Keysight、Rohde & Schwartz、Agilent,以及 9000 多个其他的测试与测量设备品牌

- 定制计划选项:现场、本地、发运到工厂

- 快速、可依赖的周转时间

- 完整系列的 Z540 和 ISO 17025 认证校准

- A2LA 认证技术人员

Lean Manufacturing

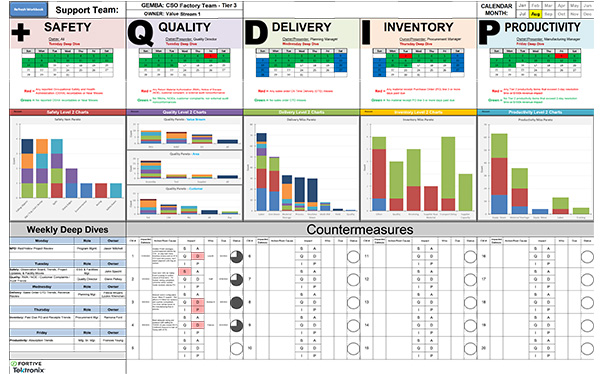

Tektronix Component Solutions applies lean manufacturing principles throughout our facility and is focused on continuous improvement to remove waste, streamline processes and ensure that assembly activities are providing value to our customers. To support this goal, our manufacturing lean cells are constantly evaluated on strict standards of safety, quality, delivery, inventory and productivity (+QDIP). +QDIP metrics are clearly communicated at each cell by a visual management system, allowing managers and operators to quickly assess performance at any given time. With these metrics as a guide, our manufacturing team consistently seeks to pro-actively enhance the design and flow of lean cells to improve performance (e.g. takt time, yield, throughput). This focus on continuous improvement helps to proactively reduce risk and ensure quality and consistent delivery.

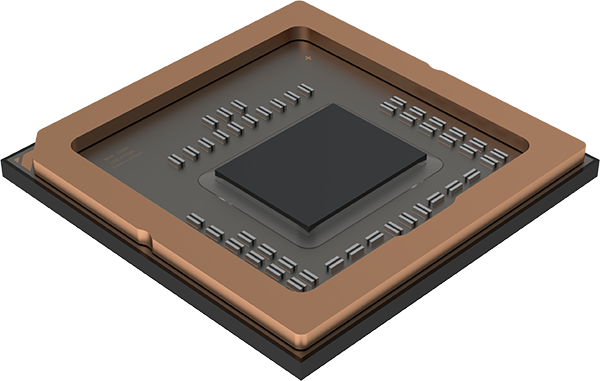

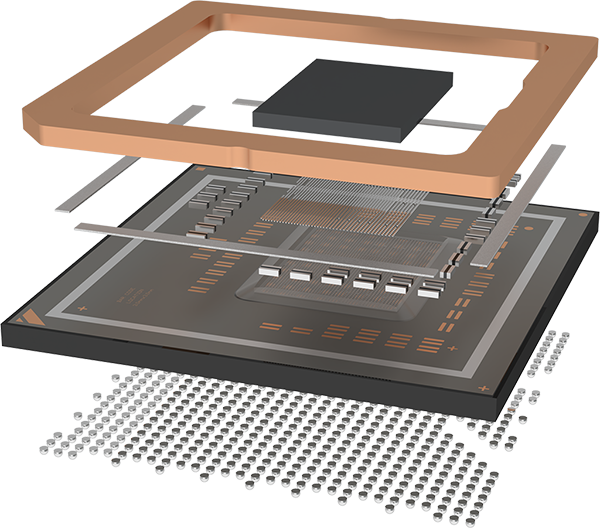

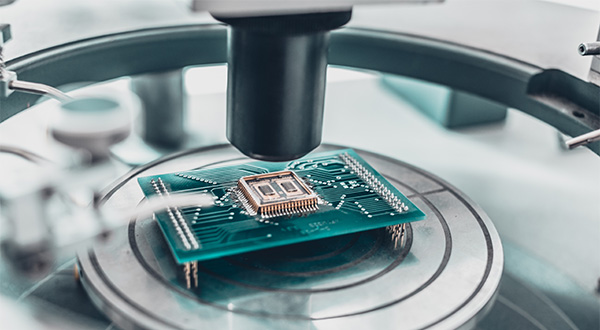

As a proven US-based, ITAR-registered supplier to a variety of defense programs and companies, Tektronix Component Solutions is an ideal partner for defense applications requiring high-performance, mission-critical microelectronics. Offering services and products that include wafer test, IC packaging assembly and test, 2.5/3D packaging, and design & simulation, Tektronix Component Solutions has the expertise and capabilities to meet your requirements for high-reliability microelectronics.

With more than 40 years of experience, Tektronix Component Solutions is the stable supplier that you can trust to deliver on long-term military programs.

Trusted, ITAR-Registered Supplier

Tektronix Component Solutions has been accredited by the U.S. Department of Defense (DOD), Defense Microelectronics Agency (DMEA) as a Category 1A microelectronics Trusted Source for IC packaging/assembly and test services – the highest designation awarded by the U.S. Department of Defense. This enables Tektronix Component Solutions to serve U.S. defense customers with classified program requirements. The accreditation certifies that Tektronix Component Solutions meets stringent product control and security standards in providing trusted microelectronic services. Tektronix Component Solutions also holds certifications in ISO9001/ISO14001 and AS9100D and meets all ITAR requirements.

As an on-shore, ITAR-registered supplier, Tektronix Component Solutions has stringent standards in-place to protect and control sensitive information related to defense programs. With many years of experience supporting defense customers and programs, we recognize and adhere to the added level of responsibility in providing microelectronic engineering and manufacturing services to the military.

High-Performance Products and Services

Our military experience spans a variety of critical applications, including communications, avionics, radar, propulsion control, and guidance systems. Tektronix Component Solutions has supplied high-performance and high-reliability products to defense programs such as the F-22 Raptor and F-35 Lightning II (Joint Strike Fighter) with a focus on continual C-SWaP (cost, size, weight and power) improvements.

Having served military and commercial aerospace customers for many years, Tektronix Component Solutions has a deep understanding of the high-reliability requirements of those applications. As such, we fully utilize our unique strength in test to deliver fully-tested parts that have proven to operate successfully in mission-critical environments.