In this installment of our series on power supply testing from start to finish, we’ll walk you through the steps for testing your prototype as it sees high voltage for the first time. In addition, we’ll offer up recommendations on the best instruments to use for these tasks.

Let’s begin by isolating the high-voltage stages from the low-voltage stages during the first power-on. We suggest using an AC power source with current limiting capabilities. Once you have selected your AC power source, start from the lowest AC voltage for your design – a crucial step, one that will help reduce the risk of major blowouts due to such potential issues as bad soldering, poor assembly or PCB design mistakes.

Now start measuring the AC input voltage and current. We recommend using appropriately-rated differential and current probes. If you are using a clamp-on current probe to measure the low AC input current draw of your unloaded system, you can actually boost the current seen by the probe. To do so, simply loop the line conductor through the jaw, multiple times. Remember to divide your current reading by the number of turns.

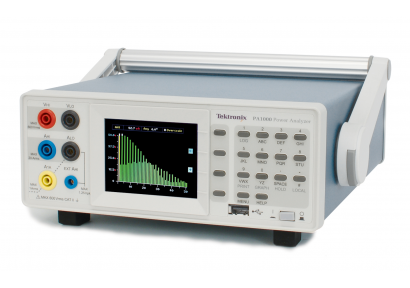

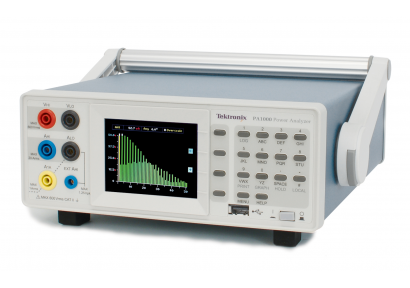

You’re almost ready to power-on your device under test. However, before you do, use a scope or a power analyzer on the AC input with logging enabled and make sure to capture the inrush currents and transients. We suggest using the PA1000 Power Analyzer, which is optimized for fast, efficient and accurate power consumption. This power analyzer also offers inrush current mode to test the peak during current inrush.

A power analyzer such as the PA1000 makes short work of AC circuit power-on testing.

If you wish to log start-up current, use a power analyzer with a continuous logging function. This will help to save your data in the event of a catastrophic failure during turn-on – something we highly recommend.

Need more insight? Try using DPOPWR scope software, which offers an extensive power analysis suite that can help you measure and debug input AC power parameters during power-on.

Here is an example of AC power analysis using DPOPWR on an MSO5000B oscilloscope

Once everything checks out, it’s time to enable the low-voltage control circuit for a complete picture.

Check back later for more in our 10-part series to learn the steps involved with checking the control logic.

See More Power Supply Measurement Tips in this 10-part series:

Part 1: Component Selection and Characterization for Power Supply Design

Part 2: Low-Voltage DC Circuit Power-On Test

Part 3: High-Voltage AC Circuit Power-On Test

Part 4: Digital and Analog Control Circuit Debug

Part 5: Testing Power Stage Switching Characteristics

Part 6: Switching and Conduction Loss Testing

Part 7: Power Supply Specification Check

Part 8: Power Line Compliance Testing

Part 9: EMI Troubleshooting and Pre-compliance

Part 10: Design Validation