As electric vehicles (EVs) continue to proliferate, understanding the infrastructure that supports them, particularly Electric Vehicle Supply Equipment (EVSE), or charging stations, becomes crucial. This guide explains what EVSE is, how it works, and why it's essential for the transition to electric mobility.

After learning about EVSE, take the next step to learn about EVSE test and measurement.

Jump to a section on this page:

- What is EVSE?

- Breakdown of EV Charger Components

- Operation and Connectivity of EVSE

- Cables and Connectors for EVSE

- EV Charging Standards: Importance and Key Guidelines

- Market and Technological Trends in EVSE

- Equipment Used for Testing EVSE Systems

- EVSE Glossary: Key Terms in EV Charging

What is EVSE?

Electric Vehicle Supply Equipment (EVSE) is the bridge that connects an electric vehicle to a power source, facilitating safe and efficient charging. They take electrical power from the grid and transfer it to an electric vehicle in order to charge the battery within the EV. They can go by different names like charging stations, EV chargers, or charge points.

Breakdown of EV Charger Components

The components of Electric Vehicle Supply Equipment (EVSE) are designed to move electrical power from the power grid to an electric vehicle safely and efficiently. Here's a closer look at the main components of an EVSE:

- Housing/Enclosure: This is the protective casing that contains all of the EVSE's internal components. It safeguards the electronics and electrical equipment from environmental factors, like rain or snow, and potential mechanical damage, like a car backing into them or vandals. The design can vary from simple wall-mounted boxes to sophisticated standalone units for public use.

- Power Input: This subsystem is responsible for connecting the EVSE to the electrical grid. It can handle various voltage and current levels, as well as phase configuration, depending on whether the EVSE is designed for Level 1, Level 2, or DC Fast Charging. Input electronics help control the impact of the EVSE on the grid, including conducted electromagnetic compatibility, harmonics, and power factor.

- Control Electronics: These are the brains of the EVSE. They manage the charging process by communicating with the connected vehicle to ensure that the correct amount of power is delivered at the right speed. This is also where the electricity used is measured for billing the user. This system includes relays and switches that can interrupt power flow for safety.

- Cable and Connector: The cable extends from the housing and ends in a connector, which plugs into the electric vehicle. The design of the connector varies by the standards it supports (such as J1722, IEC 62196, NACS, CCS, and CHAdemMO). Some connectors support only AC charging (Level 1 and or Level 2) while others support DC fast charging. In addition to power transfer, cables and connectors must carry communications signals between the EVSE and EV.

- User Interface: Most EVSE includes a user interface, which can range from simple indicator lights to advanced touchscreens that display charging status, power usage, and other operational details. EVSE may also include network connectivity like Wi-Fi or Ethernet, allowing for billing, remote management, and updates.

- Safety Mechanisms: Integral to all EVSEs are various safety features, such as circuit breakers, ground fault circuit interrupters or residual current device (GFCIs or RCDs), and thermal sensors, which help prevent overheating and electrical faults. Cables, connectors, and communication between the EVSE and the EV are designed for safe connection and charging sequencing. These systems ensure that the charging process is safe for both the vehicle and the user.

Together, these components form a complex system that plays a crucial role in the usability and safety of electric vehicle charging, providing a reliable bridge between the power grid and the vehicle.

Operation and Connectivity of EVSE

How EVSEs Operate:

Getting electrical power from the grid to an electric vehicle is all well and good, but as we saw above, EVSE is more complicated than a simple wire. Let's break down a few different ways EVSE are different from each other.

Charging Levels and Specifications:

Charging levels in EVSE vary by power source and determine how fast a vehicle charges. The definition of the levels or types varies between regions. In North America, which uses 120 V single-phase voltage and 240 V split-phase voltage in residences, the following levels apply:

- Level 1 Charging: Utilizes standard 120 VAC household outlets for slow charging. This level of EVSE is closest to being a simple wire, but there are still safety mechanisms and occasionally control electronics present. Many of the components discussed above are excluded in Level 1 EVSE.

- Level 2 Charging: Employs a 208-240 VAC supply to deliver power to the vehicle faster, resulting in faster charging. Most residential and commercial spaces either have this level of voltage available already, or can be retro-fitted with minimal effort. This level of charging is currently the most common.

- DC Fast Charging: This level of EVSE is the most complex and involves converting AC electrical power to DC power before sending it to the vehicle while Levels 1 and 2 send AC power to the vehicle. This level typically uses higher voltage and current 3-phase power that is only available in commercial or industrial settings.

In countries that have single-phase 230 VAC receptacles throughout the power system, there is no equivalent to the North American Level 1. However, power levels roughly corresponding to Level 2 are typical in international AC systems, including some systems and EVs that can handle 3-phase AC. All regions support some form of DC Fast Charging.

Note: The terms “Type 1” and “Type 2” are used to describe the pin configurations on EV power connectors. These do not correspond directly to the “Level 1” and “Level 2” charging levels used in North America.

Power Connections:

EVSEs can be connected to the grid in several ways, tailored to different needs:

- Plug-in Connections: Typically used in homes and for emergency charging for their simplicity and convenience. In North America this is the standard for Level 1 charging.

- Hardwired Connections: Necessary for higher power requirements such as Level 2 or DC fast charging, these requires professional installation.

Safety, Testing, and Maintenance:

Maintaining the safety and efficiency of EVSE is critical, necessitating regular testing and maintenance.

- Inspections and Updates: Routine checks ensure that all electrical connections are secure, while firmware updates enhance functionality and safety.

- Physical Checks: Regular inspections help to detect and address wear and tear, preserving the integrity and safety of the equipment.

Connectivity Explained:

Modern EVSE leverages network connectivity to enhance both user experience and operational efficiency. Key features include:

- Remote Monitoring: Enables both users and service operators to monitor charging sessions and manage energy consumption from afar.

- Smartphone Control: Offers users the convenience to start, stop, and schedule charging via a smartphone application.

- Smart Home/Building Integration: Connects with home energy management systems to optimize electricity use, integrating smart features such as adaptive solar energy consumption. Utilities may offer discounts in return for being able to throttle charging during periods of high demand.

Cables and Connectors for EVSE

The role of cables, and connectors in EVSE systems is crucial for ensuring the safe, efficient, and effective charging of electric vehicles. Here's a deeper look:

Cables

Engineered for durability and safety, charging cables need to handle significant currents while maintaining flexibility and standing up to heavy use. Generally, their thickness varies by charging level, with thicker cables required to support higher amperage.

Connectors

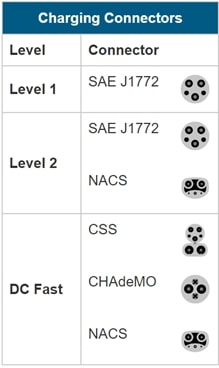

Available in several types, connectors must match vehicle standards and are equipped with safety features like thermal sensors and locking mechanisms. Naturally, they need to mate with the matching port on the EV or be made compatible through an adapter. The standard connectors are:

J1772 (Type 1): Primarily used in North America for Level 1 and Level 2 charging.

IEC 62196 (Type 2): Used in Europe and integrated into CCS for DC fast charging. It can also handle 3-phase AC in certain electrical systems.

CHAdeMO: Japanese standard for DC fast charging, notable for its large size and for being one of the earliest connector standards.

CCS (Combined Charging System): Integrates AC and DC charging into a single connector, widely adopted in Europe and North America for fast charging. CCS1 uses the Type 1 connector with 2 added pins to carry DC current. CCS2 does the same but uses the Type 2 connector.

J3400 (NACS): Previously a propriety standard from Tesla that is now available for broader use, this connector is being adopted by much of North America for the future. It is designed to handle all levels of charging.

EV Charging Standards: Importance and Key Guidelines

Introduction to EV Charging Standards

Electric Vehicle Charging Stations are vital components of the EV ecosystem, governed by standards that help to ensure safety, efficiency, and compatibility:

- Safety: Standards prevent overloading and electrical fires, ensuring that connections are secure before power is transmitted.

- Interoperability: Ensures different vehicle models can use various charging stations safely and without issues.

- Power quality standards and electrical codes: These codes and standards regulate the connection to the electrical system and limit the allowable impact of charging stations on the grid – for example power factor and harmonics.

Major Standards Organizations

In addition to local electrical codes, several bodies develop and enforce standards for EVSE:

- IEC (International Electrotechnical Commission): Focuses on electrical systems, producing standards like IEC 61851 for electromagnetic compatibility, EVSE types and communications, as well as IEC 62196 for connectors.

- IEEE (Institute of Electrical and Electronics Engineers): Specializes in electronics and electrical engineering, setting guidelines for safety and technology integration.

- SAE (Society of Automotive Engineers): Develops standards for manufacturing and testing EV components, ensuring they meet rigorous automotive requirements.

- GB (National Standards of the People’s Republic of China): Develops standards for EVSE in China, such as GB/T 20234.

The standards created by these bodies foster a reliable, safe, and user-friendly environment for electric vehicle charging, contributing to the broader adoption of EVs globally.

Learn More About EV Charging Standards

Market and Technological Trends in EVSE

The realm of Electric Vehicle Supply Equipment (EVSE) development is dominated by a few exciting technologies that promise to make EV charging more efficient and accessible:

- Enhanced Charging Speeds: Ongoing advancements are consistently aimed at reducing charging time, making it comparable to or faster than traditional fueling methods.

- Wireless Charging Developments: Steady progress in wireless charging technologies suggests a future where EVs can be charged effortlessly, eliminating the need for physical cables.

Predictions for Sustained Developments:

Seamless Integration with Renewable Resources: Future EVSE technologies are expected to harmonize more effectively with renewable energy, promoting environmental sustainability and reducing dependency on traditional power sources.

- Advancements in Smart Charging Capabilities: Innovations are likely to further refine the intelligence of charging systems, enabling them to adapt charging schedules based on real-time energy demand and pricing.

- Expansion of Vehicle-to-Grid (V2G) Systems: As V2G technology matures, it is anticipated to become more widespread, allowing EVs to contribute back to the power grid and enhance grid resilience.

These trends indicate a trajectory towards a more integrated, efficient, and user-centered EV charging infrastructure, continuously adapting to the evolving needs of the market and technology.

Equipment Used for Testing EVSE Systems

To ensure safety, reliability and efficiency, EVSE systems are rigorously tested during the design process, during manufacturing, and in the field. Here's an overview of the key types of test equipment used.

General Test and Measurement

During the design and manufacturing process, oscilloscopes, digital multimeters, signal generators, power supplies, electronic loads, and power analyzers are used to help bring up new designs and confirm that EVSE is operating within specifications.

Pictured in the image above:

- Oscilloscope (in the center): Utilized for visualizing and analyzing the waveforms of electrical signals within the EVSE. This can be used to ensure the proper functioning of the pilot signal between the vehicle and the charging station, to observe the quality of the power supply, and to check for any noise or interference that might affect the charging process.

- Arbitrary Function Generator (to the left of the oscilloscope): Used to simulate various signal conditions that the EVSE might encounter when interfacing with different electric vehicles. This device can help in stress-testing the EVSE’s response to irregular signals or to mimic vehicle communications for testing purposes.

- Source Measure Unit (SMU) (to the far left): Employed to accurately measure the electrical parameters such as voltage, current, and resistance in the EVSE modules and components. It ensures the output is within specified tolerances and that the charging station is safe and efficient. It may also be used for diagnostic purposes when troubleshooting EVSE faults.

- Power Supply (below the SMU): Provides a stable and adjustable source of power to emulate different charging conditions. A low wattage power supply, like the one shown, can be used to power modules and subsystems during testing. A high wattage supply such as an EA 10000 series bidirectional power supply can be used to emulate a vehicle's battery system for DC fast charging, or emulate abnormal conditions during development or testing.

These devices are used to simulate vehicle connections and assess the EVSE's response, verifying compliance with standards such as IEC 61851 and SAE J1772. They can check for correct signaling, timing, and the delivery of power.

- Functional testers and test adapters are used to simulate an EV connection to verify the EVSE's operational functions.

- Test adapters facilitate the connection of digital multimeters or oscilloscopes.

- Protocol analyzers check communication protocols to ensure compatibility with various vehicle models.

Network Connectivity Testers

These tools evaluate the EVSE's ability to communicate with remote monitoring systems, ensuring that features like smart charging and firmware updates function properly. The two main types of equipment used for testing connectivity are as follows:

- Network analyzers assess the ability of the EVSE to communicate with central systems.

- Wi-Fi testers ensure the reliability and security of wireless connectivity features.

Electrical Safety Analyzers

Critical for ensuring that the EVSE operates safely, these analyzers test protective mechanisms, grounding, insulation, and the presence of any potentially hazardous electrical faults. These generally fall into the following types:

- Insulation resistance testers measure the integrity of electrical insulation.

- Ground fault circuit testers detect faults in the grounding system to prevent electrical hazards.

- Power quality analyzers these instruments measure the impact of EVSE on the electrical grid, including voltage levels, current, frequency stability, power factor, and harmonics.

EVSE Glossary: Key Terms in EV Charging

- EVSE (Electric Vehicle Supply Equipment): The hardware or infrastructure that delivers electric power to recharge electric vehicles, commonly referred to as charging stations.

- Level 1, 2, and DC Fast Charging: These terms refer to the different speeds and power specifications for charging electric vehicles. Level 1 is the slowest form, using standard household outlets, while Level 2 is faster and uses a higher voltage. DC Fast Charging represents the quickest charging technology, utilizing direct current (DC).

- V2G (Vehicle-to-Grid): Technology that allows energy to be returned from the electric vehicle’s battery to the power grid.

- Smart Charging: Refers to charging systems that optimize energy use by automatically adjusting charging times based on grid load and electricity rates.

- Interoperability: The ability of EVSEs to operate with electric vehicles of different makes and models without compatibility issues.

- Demand Response: Technology that adjusts the charging rate based on utility signals to prevent grid overload during peak energy-use periods.

- Firmware: Software programmed into the hardware of an EVSE that controls the charging process, communications, and user interaction.

- Grid: The network of power lines and associated equipment used to distribute electrical energy around a community.

- Charger Topology: Describes the configuration of an EV charging station in terms of its architecture and how it connects to the grid and the vehicle.

- DC Fast Charger: A type of EVSE that delivers a high power output directly using DC (Direct Current), significantly reducing charging time.

- Interoperability: The ability of different makes and models of EVSE and EVs to work together.

- J1772: The standard connector type for Level 1 and Level 2 charging in North America, which provides AC power to the vehicle.