联系我们

与泰克代表实时聊天。 工作时间:上午 9:00 - 下午 5:00(太平洋标准时间)。

致电我们

工作时间:上午9:00-下午5:00(太平洋标准时间)

下载

下载手册、产品技术资料、软件等:

反馈

Advantages of Interlock System on the MP5000 Series

Advantages of Interlock System on the MP5000 Series

Enabling Safe, Confident Testing in Power Semiconductor and Discrete Device Characterization

As voltage and current levels increase to meet the demands of advanced power devices, the risk of electric shock, arc-over, or accidental misconfiguration grows. Ensuring operator and equipment safety is not just a best practice—it is a regulatory requirement in high-power test environments such as semiconductor characterization, power module evaluation, or high-current sourcing.

The Tektronix MP5000 Modular Precision Test System addresses these concerns with a hardware-enforced safety interlock. This feature automatically turns off all outputs unless the test environment is verified as enclosed and safe. Unlike some modular systems, when the MP5000 interlock operates, it locks out all modules in the mainframe. This feature eliminates the risk of partial disablement or user override.

Key Benefits:

- Prevents unintentional sourcing of hazardous voltages

- Integrates with test fixture lids, chamber doors, emergency stops, and light curtains

- Provides comprehensive protection across all modules with minimal setup

Why have a Safety Interlock?

Working with outputs above 50 V DC introduces shock hazards. A safety interlock ensures that test signals are only active when external safeguards—like lid switches or safety chambers—are properly engaged.

According to IEC definitions, voltages above 60 V DC exceed the limits for Safety Extra-Low Voltage (SELV), a classification for circuits safe to touch under normal conditions. OSHA regulations (e.g., 29 CFR 1910.303(g)(2)(i)) further mandate guarding of all “live parts of electrical equipment operating at 50 volts or more,” whether AC or DC.

When working with voltage outputs at or above these ranges, unintentional contact or misconfiguration can pose serious safety risks. The safety interlock ensures that the output is only enabled when a closed-loop signal confirms that external safety mechanisms (like test enclosures or interlock switches) are active.

What Is a Safety Interlock?

A safety interlock is a hardware-level mechanism that links output enablement to the physical safety state of the test setup. When an unsafe condition occurs—such as an open fixture lid or exposed terminal—the interlock turns off the system outputs. Typical implementations include lid-activated microswitches or chamber door sensors.

This interlock ensures that using the MP5000, no high-voltage sourcing can occur unless a closed-loop signal confirms a safe test environment. The system is fail-safe by design: if the interlock signal is lost or the connection is incorrect, outputs are disabled.

How It Works

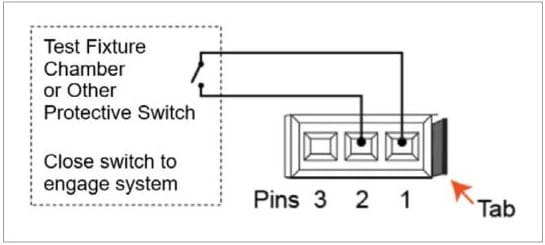

The MP5000 Modular Precision Test System includes a dedicated interlock input pin on a rear-panel connector. This pin must receive a closed contact (short) signal from an external safety device, or the output terminals of each channel across all modules automatically disconnect.

The mainframe provides user feedback through front panel LED indicators and a message on the LCD screen. The web interface also displays a dialog message explaining that the open interlock has disabled all outputs.

The Operation Status Register provides the interlock’s status. The following TSP commands return the status of the interlock.

statusByte = status.operation.condition --

Read the Operation Status Register

interlockEngaged = bit.test(statusByte,

8) -- Check value of bit 7 (position 8),

the interlock bit

print(interlockEngaged) -- Prints true if

interlock is engaged, false if not

Specifications

| Fail-Safe Mode | Output disabled on open loop |

| Input Connector | 3 Position Rectangular Plug Tektronix P/N CS-1616-3 3M P/N 37103-A165-00E MB |

| Max Path Resistance | 10 Ω |

| Wire Gauge | 20 to 24 AWG |

|

|

For more information on assembling the interlock, see the MP5103 Modular Precision Test System User’s Manual.

Application Examples

- Battery Cell Testing: Prevents high-voltage sourcing when rack doors are open.

- Power Semiconductor Probing: Used with interlocked probe stations to prevent DUT exposure.

- Automated Test Systems: Integrates with external safety systems to meet compliance standards.

Requirements / Notes

- Any voltage can be dangerous under the right circumstances.

- Mechanical detection switches should be rated appropriately and carry safety approvals. Periodically test the interlock circuit to ensure reliable operation.

- Never bypass the interlock. Doing so may expose users to hazardous conditions that could cause serious injury or death.