联系我们

与泰克代表实时聊天。 工作时间:上午 9:00 - 下午 5:00(太平洋标准时间)。

致电我们

工作时间:上午9:00-下午5:00(太平洋标准时间)

下载

下载手册、产品技术资料、软件等:

反馈

优化您的电池回收

提供高效能源回收与电池测试系统,全面优化电池回收流程的每个环节。

对于梯次利用场景,我们的双向直流电源能够对退役电池进行精确测试和调节,将超过 96% 的能量回馈给电网。在电池最终回收阶段,我们的回馈式电子负载系统通过安全可控的放电流程与能量回收技术,同步实现风险管控与能源再利用的双重目标。

这些技术能够帮助回收企业有效降低成本、提升安全性,并助力构建更具可持续性的电池循环经济体系。

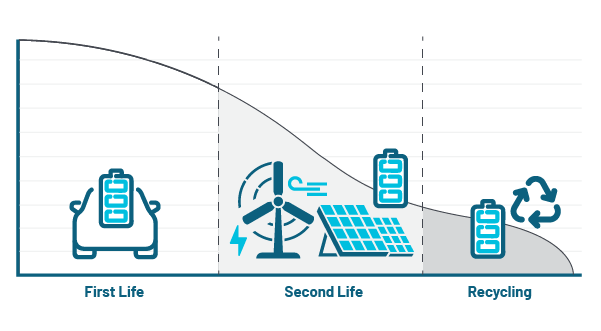

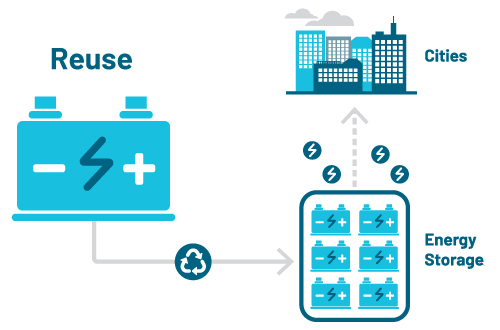

梯次利用

双向直流实验室电源测试电池的剩余容量

主要目标是为电动交通领域退役的电池寻找二次应用场景(梯次利用)。例如,作为用于太阳能或风能的储能装置。在测试电池剩余容量时,首先需将电池完全充电,然后以受控方式进行放电。此过程将测量容量 (SOC) 和老化状态 (SOH),并以超过 96% 的效率将能量回馈至电网。

双向可编程直流电源

对于此类应用,采用双向实验室电源进行深入研究是合理的选择。仅需一台设备,即可测试电动车辆淘汰的旧电池是否仍能满足其他应用场景的二次利用需求。若这些应用场景主要为静态用途,且电池的剩余容量充足,那么这些电池将实现二次利用,例如应用于固定式储能系统。

在此项测试中,首先使用双向电源为电池充满电,随后通过同一设备以受控方式对电池进行放电。系统会测量电池的容量(SOC)和老化状态(SOH),并以超过96%的效率将能量回馈至电网。

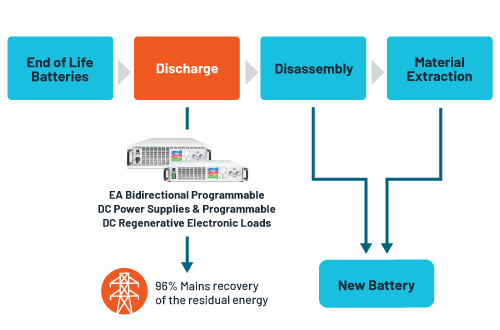

最终回收

高效、安全和可持续

为实现锂离子电池回收或梯次利用的经济效益,所有流程都必须以最高效率运行。由于锂离子电池和锂离子聚合物电池在服役期间不应该完全放电,因此可以假定大多数待处置电池最终都会有残余容量。电池在进行实际回收之前,必须完全放电。

带电网回馈功能的电子负载可用于对蓄电池进行完全放电。

在梯次利用结束后,可充电电池将进入最终回收阶段。这个过程旨在尽可能多地回收锂离子电池的各个组件,并将其作为原材料用于制造新的电池。在将电池拆卸成单个部件之前,必须将其完全放电。这样做是为了规避接触危险电压或火灾风险,同时利用电池中存储的剩余能量。

EA Elektro-Automatik 的回馈式电子负载是针对此目的的高效解决方案。

双向可编程直流电源的优点

在测试电池容量时,实现高效率和更高的安全性

EA Elektro-Automatik 的双向可编程直流电源可确保电池尽可能充分地充放电。通过精确测试,为 DUT 提供有关剩余容量的详细数据。

节省时间,提高经济效益

采用高达15kW(3U机箱)或30kW(4U机箱)的高输入功率对锂离子电池进行充放电,可显著缩短时间,从而有效提升成本效益。此外,这些设备可组合成高性能开关柜系统,总输出功率高达 1.92 MW。

EA 的 60kW (6U机箱)双向可编程电源支持并联运行,总功率可达3.84 MW,以其紧凑的模块化配置,为高吞吐量测试提供了高效的能源回收解决方案。

通过能量回馈实现成本分摊

EA 的双向可编程直流电源 在放电过程中从连接的电池中获取能量,并以高达 96% 的效率将其转换为交流电压。然后将其回馈到 当地电网并重复利用,从而通过降低电力成本 来分摊购买价格。

高度灵活地应用

功能多样且灵活:得益于EA 产品的真正自动量程功能,仅需一台双向可编程直流电源,即可对不同系统电压的电池储能系统进行充放电测试。例如,使用同一台设备即可为400V和800V系统提供全额功率输出。